I never really liked the Dremel job...not precise enough for my taste. Recently, I learned to operate a laser cutter. What better first project than designing a nice adapter plate, which would align the new switches precisely to their compartments??

I cut the adapter platelets from 5/64 plexiglass (this is a bit too thick, but that is all I had at that point). That meant I still had to put the Dremel to them to reduce the thickness of the tab areas to about 3/64, the thickness of the high density board. If I do it again, I will cut the entire adapter board from 3/64 plexi or something similar. This shows the new switches in comparison with one of the old ones and the laser cut adapters. Note the slits, the board mounting guides of the switches fit snugly into them, aligning the switch (BTW: I used No.: 611-S201031MS02Q from Mouser) with the adapters.

Here after glueing the adapters to the switches and Dremeling the tabs thinner:

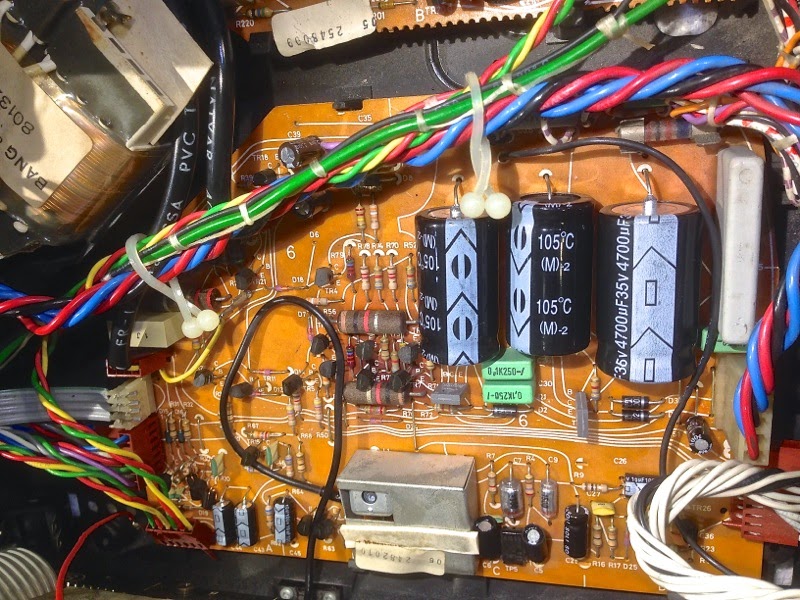

Here are a few pictures from the installation process:

Original switches removed from their compartments for desoldering:

New switches installed (it surprised me how durable the plexiglass was during soldering...no issues with melting, warping etc...):

In their compartments:

And with heat sink cover installed:

Perfect!! These new switches are much smoother than the old ones and are guaranteed for a few million switchings! On to the display board!

+Before.jpg)

+After+III.jpg)